Fused Almag Spinal

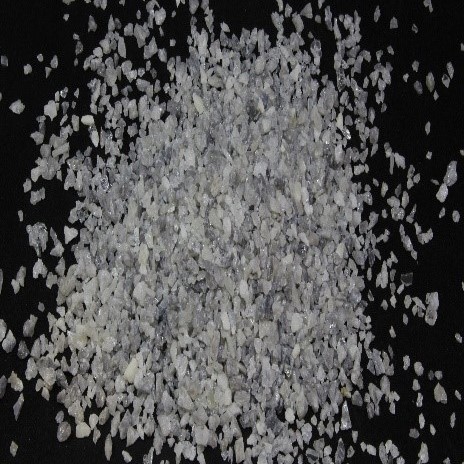

Fused Magnesia-Alumina Spinel is produced by melting high purity alumina and magnesia together, in the proper ratios, in electric arc furnaces. The resulting Fused Spinel has very large crystals and exhibits excellent corrosion resistance to molten metals and slags, thermal shock resistance, and good hot strength.

Fused Magnesia - Alumina Spinels are used mainly for refractory applications.

| Material | |||

|---|---|---|---|

| Specifications | Almag 22/MA 78 | Almag 32/MA 67 | Almag MA 90 |

| Al2O3 | 74-78 % | 64-70 % | 88-92% |

| MgO | 20-24% | 28-34% | 8-12% |

| Fe2O3 | 0.30% max | 0.40% max | 0.30% max |

| Cao | 0.45% max | 0.5% max | 0.3% max |

| SiO2 | 0.40% max | 0.40% max | 0.20% max |

| Na2O | 0.40% max | 0.40% max | 0.40% max |

| Moisture | 0.1% max | 0.1% max | 0.1% max |

| Size | -200 mesh, 1-3mm,0.2-1mm,0.5-1mm, As required | 0-0.09 mm, '-325 mesh, As required | '0-0.5 mm, -325 mesh, As required |