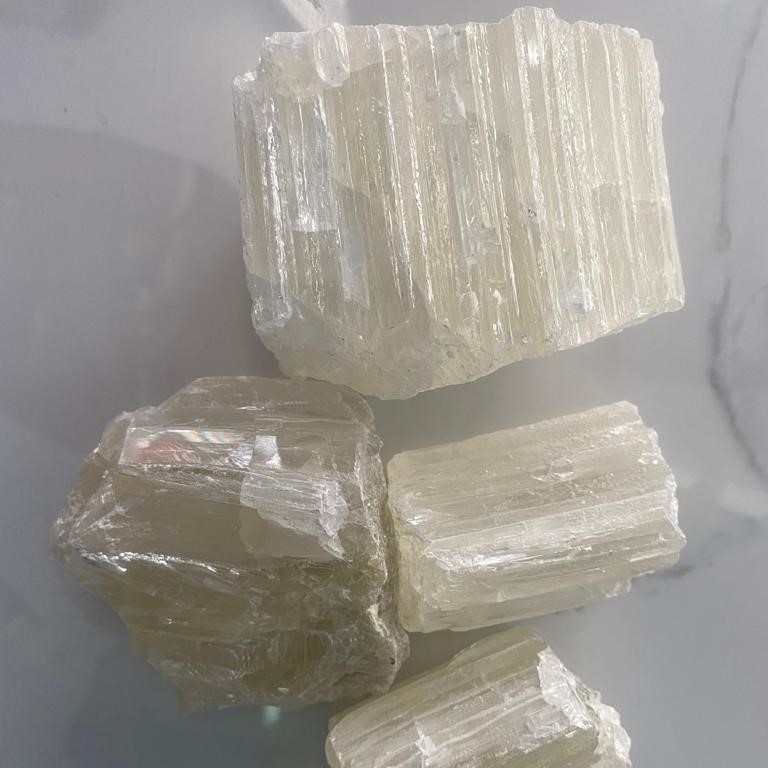

Fused Magnesite : FM

Fused Magnesia (MgO) is normally manufactured by the electric arc melting of caustic calcined magnesia, dead burned magnesia or high grade raw magnesite in furnaces at temperatures in excess of 2750°C, producing a refractory product. Fused magnesia is produced in a three phase electric arc furnace. The process promotes the growth of very large crystals of periclase ( greater than 1000 microns compared 100 microns for dead burned magnesia) with a density approaching the theoretical maximum of 3.58 g/cc.

Fused magnesia is superior to dead burned magnesia in strength, abrasion resistance and chemical stability. Major applications are in refractory and electrical insulating markets.

| Specifications | Material | |||||

|---|---|---|---|---|---|---|

| FM 97 1:1 | FM 97 2:1 N | FM 98 2:1 N | FM 97 2:1 LC | FM 97.5 2:1 LC | FM 98 2:1 LC | |

| MgO | 97.0% min | 97.0% min | 97.5-98.0 min% | 97.0% min | 97.5% min | 98.0% min |

| SiO22 | 1.20% max | 0.75% max | 0.65% max | 0.75% max | 0.6% max | 0.45% max |

| FE2O3 | 0.80% max | 0.75% max | 0.50% max | 0.70% max | 0.70% max | 0.50% max |

| CAO | 1.20% max | 1.60% max | 1.30% max | 1.30% max | 1.30% max | 1.00% max |

| AL2O3 | 0.20% max | 0.20% max | 0.20% max | 0.20% max | 0.20% max | 0.15% max |

| C/S ratio | 1 | 2 | 2 | 2 | 2 | 2 |

| Crystal Size | 800 -1000 Micron | 800 -1000 Micron | 900 -1200 Micron | |||

| BD | 3.48-3.5 G/CC min | 3.48-3.5 G/CC min | 3.48-3.5 G/CC min | 3.48-3.5 G/CC min | 3.48-3.5 G/CC min | 3.5 G/CC min |

| Size | 3-5 mm, 1-3 mm,0-1 m, As reuired | 0-1 mm, 1-4 mm, 10-100 mm, As required | 0-40 mm/50 mm/100 mm/125 mm, AS required | 10-100 mm, As required | 10-100 mm, As required | As required |