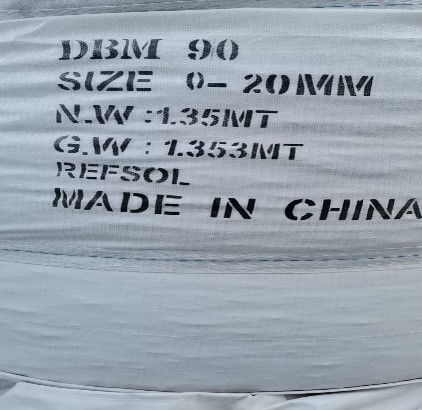

Dead burnt Magnesite : (DBM)

Magnesite, from both natural sources (primarily magnesite) and synthetic sources (seawater, natural brines or deep sea salt beds), is converted into calcined magnesia by calcining to between 700 deg C and 1000 deg C, driving off most of the contained CO2. Calcined magnesia is both an end product and an intermediary step in the chain of magnesia products.

Further calcining of magnesite at higher temperatures between 1500 deg to 2000 deg C results in the largely inert product, dead burned magnesia. Heating to this level drives off all but a small fraction of the remaining CO2 to produce a hard crystalline non reactive form of magnesium oxide known as periclase. Dead burned magnesia exhibits exceptional dimensional stability and strength at high temperatures.

These products are well suited in the manufacture of refractory bricks, monolithic gunning refractories, specialty refractory applications (precast shapes and castables), LCD glass, drilling fluids and cements, and other applications.

| Specifications | Material | ||

|---|---|---|---|

| DBM 90 | DBM 95 | DBM 97 | |

| MgO | 90.00% min | 95.00% min | 97.00% min |

| Sio2 | 5.00% max | 2.00% max | 0.65% max |

| Fe2O3 | 1.80% max | 0.50% max | 0.80% max |

| CaO | 2.50% max | 2.00% max | 1.50% max |

| Al2O3 | 1.50% max | 0.50% max | 0.20% max |

| BD | 3.10 g/cc min | 3.20 g/cc min | 3.30 g/cc |

| Sizes Available | 0-30 mm, 0-1 mm,1-3 mm , As required | 0-30 mm, As required | 0-30 mm , As required |