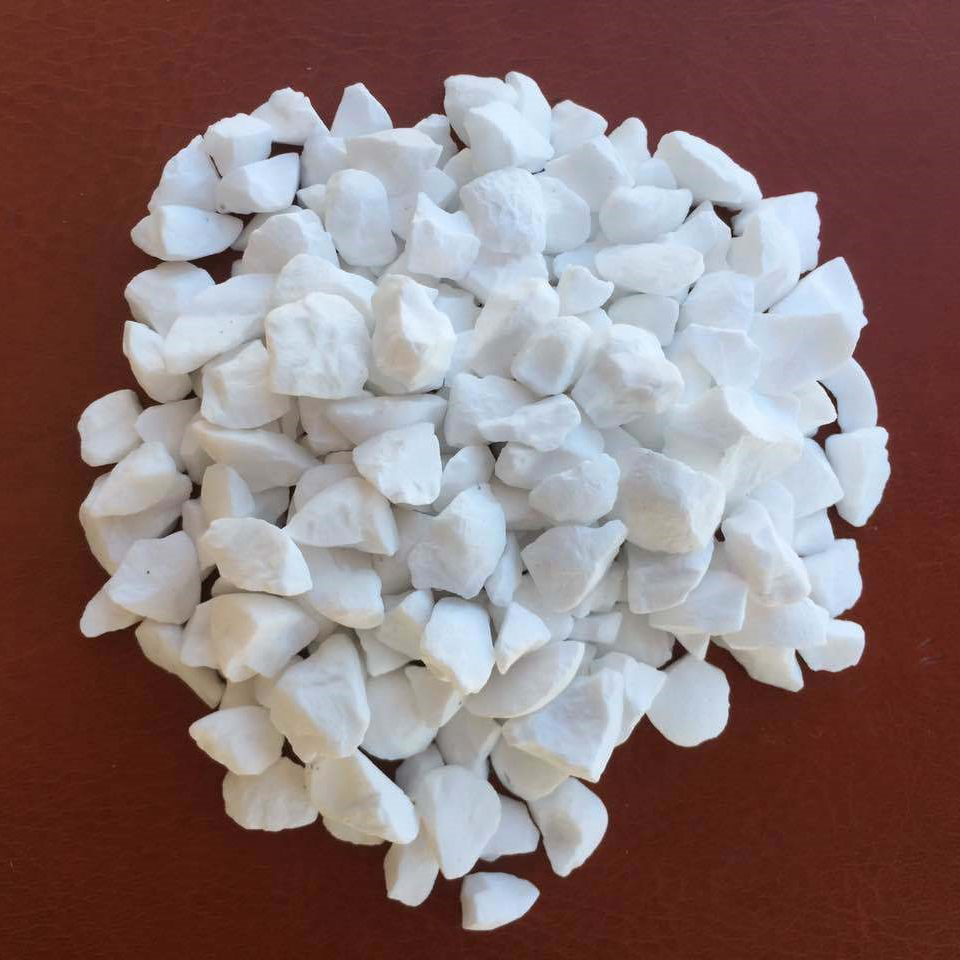

Tabular Alumina (WTA)

Tabular Alumina is a pure sintered α-alumina material that has been fully densified by rapid-sintering without the use of sintering aids at temperatures in excess of 1800 degree celsius. The excellent thermal volume stability and thermal shock characteristics can be attributed to its specific microstructure: low open porosity and large crystal with closed spherical pores, which are entrapped upon re-crystallizations during rapid sintering. Tabular alumina has extremely high refractoriness, high mechanical strength and abrasion resistance, very good chemical purity, excellent dielectric properties and good resistance against acid and alkali corrosion.

| Material | ||

|---|---|---|

| Specifications | WTA | WTA Grade 2 Fines |

| Prime | Typical values | |

| Al2O3 | 99.20-99.40 min% | 99.00% |

| Fe2O3 | 0.10 %max | 0.08% |

| SiO2 | 0.10 %max | 0.08% |

| CaO | 0.1%max | |

| Na2O | 0.40% Max | 0.70% |

| B.D. | 3.50-3.60 g /cc min | |

| Size | Graded: 0-0.5/0.2-0.6/0.5-1/0-1/1-2/1-3/3-5/5-10 | 300-500 Mesh, |

| Fines: -200/325 mesh | 500-1000 Mesh | |